surface grinding machine ppt

Metal Cutting Manufacturing Processes Outline Metal Cutting Chip Formation Processes Control Conditions Back rake angle Shear angle Chip Formation Continuous formation Built up edge formation Discontinuous formation Effects Chip formation Shear angle Chip Formation Processes Shaping Turning Milling Drilling Sawing Broaching Grinding Machining Operations Machining. 291 Surface grinding machine.

Grinding Ppt Video Online Download

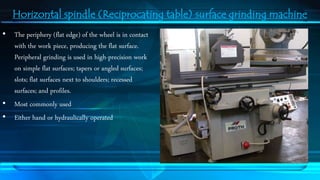

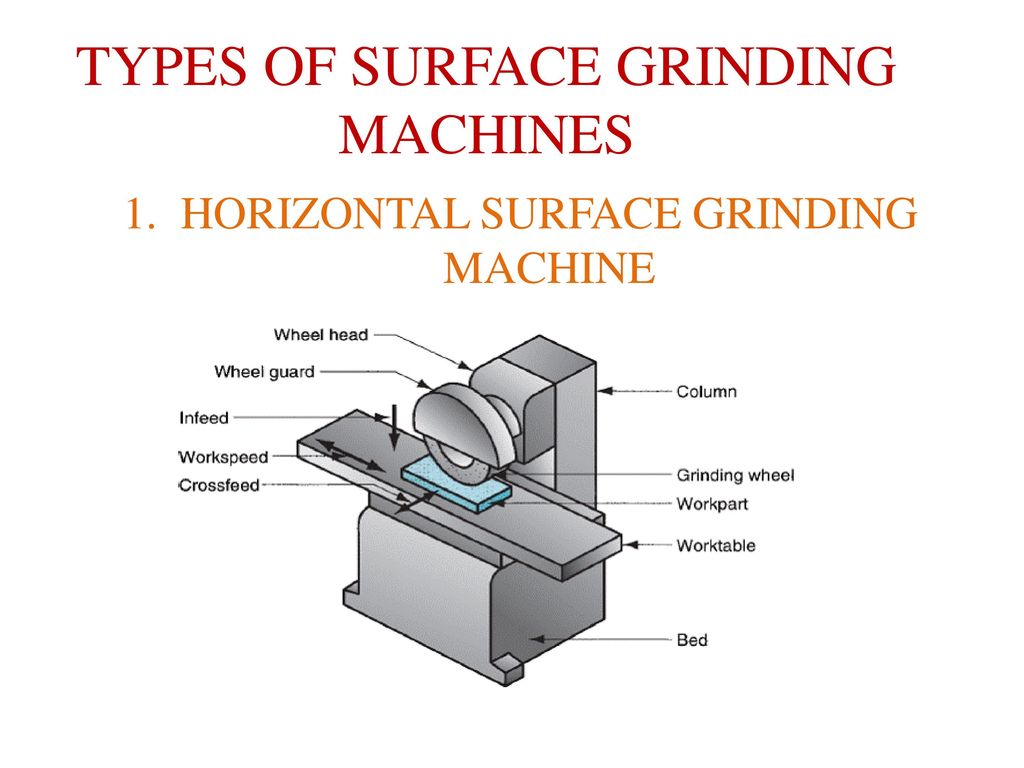

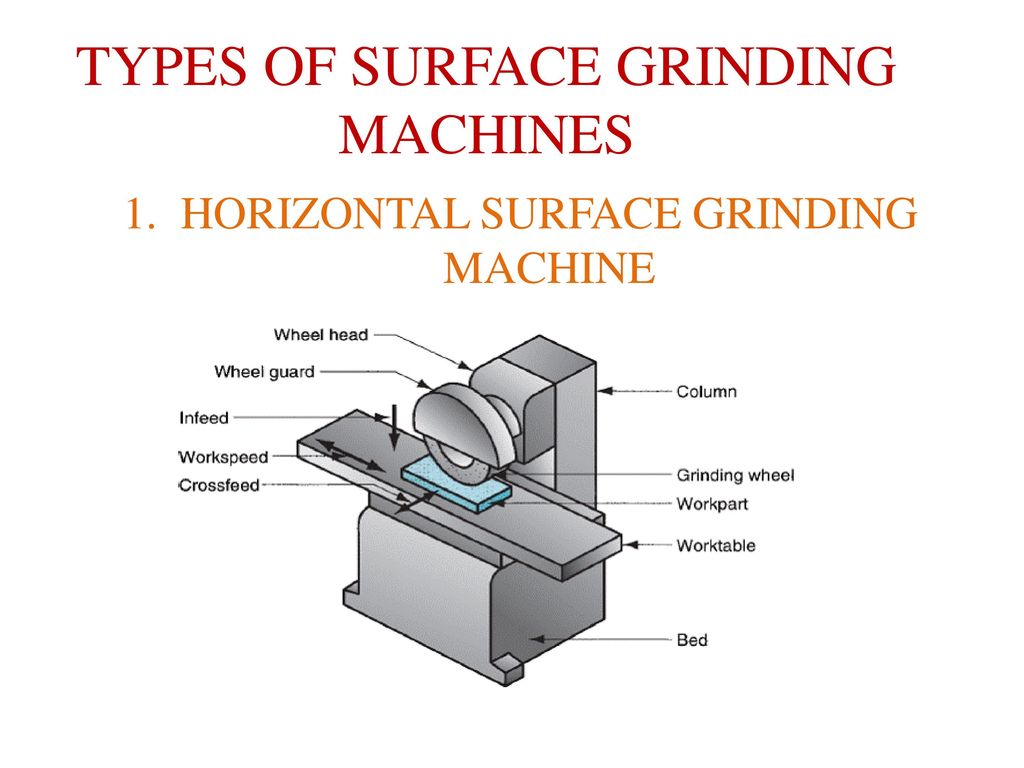

Horizontal spindle and reciprocating table type 2.

. Roughing and finishing flat cylindrical and conical surfaces. SURFACE GRINDING MACHINE FIG. Vertical spindle and rotary table type Horizontal spindle surface.

These grinding machine ppt are eco-friendly and are energy-saving machines for commercial uses. According to the quality surface finish. Introduction A grinding machine often shortened to grinder is any of various power tools or machine tools used for grinding which is a type of machining using an abrasive wheel as the cutting tool.

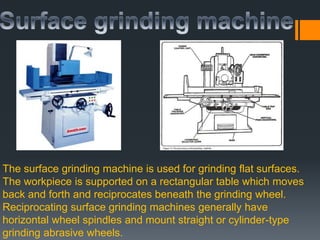

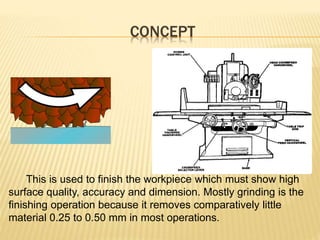

Finishing internal cylinders or bores. The grinding machine is used for 1. Surface grinding machine This machine may be similar to a milling machine used mainly to grind flat surface.

To avoid injuries follow the safety. Grinding Classification of grinding machine. Crankshaft Grinding Machine Grinding of Crankshaft - RA Power Solutions undertakes crankshaft repair of damaged crankshaft counter weight and bolts thread.

However some types of surface grinders are also capable of producing contour surface with formed grinding wheel. A distinguishing feature of grinding machines is the rotating abrasive tool. Wajid Mustafa Mughal 12-BSM-341.

Looking For Stump Grinding Services Auckland - RVS Contracting is a contracting company based in Auckland. Plain or beveled faces are available. Aim To create overall awareness about Grinder safety.

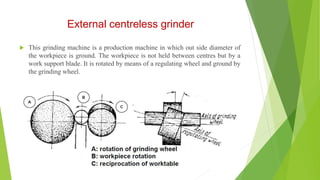

PowerPoint PPT presentation. These machines can be used for either rough or precision grinding and they come in a variety of sizes to suit many different needs. The cylindrical grinding operation is two types.

Cnc Grinding Machine PowerPoint PPT Presentations. This type of grinding operation is performed only for cylindrical jobs. Vertical spindle Reciprocating table surface grinding machine These machines are designed for quick flat grinding of work pieces.

Surface grinding machines are employed to finish plain or flat surfaces horizontally vertically or at any angle. We provide other services apart from stump grinding like tree removal service land restoration clearing stump grinding forestry mulching cultivation orchard planning planting lifestyle. Surface grinding machines are designed to produce a smooth flat finish on the metal.

This machine may be similar to a milling machine used mainly to grind flat surface. Material creating a flat surface. Flat Angular Irregular surfaces 8.

The work piece is fed against a constantly rotating abrasive wheel so that a thin layer of material is removed from the it. Basically there are four different types of surface grinding machines characterised by. The grinding machine ppt are provided with powerful motors and working mechanisms that efficiently grind stones spices leaves and so on into fine powders for a variety of uses.

The bulk grinding wheel workpiece interaction as given in Figure 2 can be divided into the following. Interrupted cutting occurs in them subjecting the tool to an impact loading upon entry into the work. ONSITE CRANKSHAFT GRINDING MACHINE 1 - in situ crankshaft grinding portable crankshaft grinder onsite crankshaft grinding machine.

A grinding machine consists of the following parts. Longitudinal travel 550mm to 800mm Spindle drive. SURFACE GRINDING MACHINE This machine may be similar to a milling machine used mainly to grind.

With a resinoid bond it is useful for snagging. However advent of new generation of grinding wheels and grinding machines. Manufacturing Technology Grinding Machines Grinding Machines are also regarded as machine tools.

Its face may be plain or beveled. However some types of surface grinders are also capable of producing contour surface with formed grinding wheel. Surface grinding uses a rotating abrasive wheel to remove.

CNC Gantry Machine CNC machine. Ppt pedestal grinding machine Use of Portable Grinders OSH Answers Use of Portable Grinders CLOSE ALL Ensure that a machine will not operate when unattended by checking the dead-man constant pressure switch Right-angle grinder the grinding face of the wheel or disc is at an angle of between 5 and 15 degrees from. Grinding machine is employed to obtain high accuracy along with very high class of surface finish on the work piece.

Metal surface grinders are an important part of any metalworking shop. Basically there are four different types of surface grinding machines characterised by the movement of their tables and the orientation of grinding wheel. There are four different types of surface grinders.

15 KW to375 KW Wheel clearance. Rough grinder Floor and bench swing frame portable abrasive belt grinder 2. GRINDING MACHINES Grinding is a material removal and surface generating process used to shape and finish components made of metals.

SAFETY PRECAUTIONS Grinding machines are used daily in a machine shop. It is basically a finishing process employed to produce high accuracy and surface finish. Up to 200mm Cross traverse is manual for infeed and powered for positioning Hydraulic drive for table.

Horizontal spindle and rotary table type 3. The grinding wheel consists of sharp crystals called abrasives held together by suitable bonding. These machines are limited to low speeds due to their start-.

It is a cast-iron casting rests on the floor and supports the other parts which are mounted on it. There are several types of grinding machines such as surface grinders bench grinders cylindrical grinders tool and cutter grinders jig grinders gear grinders profile grinders and special purpose grinders. PRINCIPLE OF SURFACE GRINDING Principle.

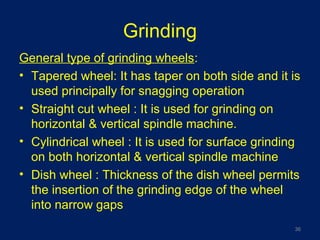

Advent of advanced grinding machines and grinding wheels has elevated the status of grinding to abrasive machining where high accuracy and surface finish as well as high material removal rate can be achieved even on an unhardened material. A grinding disc is a sharp cutting tool with thousands of cutting edges on the side of the surface. Dish The chief use of the dish wheel type number 12 is in tool work.

Vertical spindle and reciprocating table type 4. Surface grinding but can also be used for offhand grinding of flat surfaces. Precision grinder Cylindrical surface internal tool cutter disc thread cam shaft grinder 4.

An ellipse a cam or a crankshaft. Cutting tools used in both operations are single-edge cutting tools to create a straight and flat surface. Ppt Pedestal Grinding Machine Magazene.

Flaring Cup The flaring cup wheel type number 11 is commonly used for tool grinding. Each grain of abrasive on the wheels surface cuts a small chip from the work piece via shear deformation. Shaping Planning Machines Shaping and planning are similar operations.

Parts of a Grinding Machine. The combination of metal stitching metal locking and use of helicoil thread inserts is done for successful repair of crankshaft. If you are looking for stump grinding in Auckland then you should RVS Contracting.

Design And Fabrication Of Low Cost Surface Grinding Machine Ppt Download

Design And Fabrication Of Low Cost Surface Grinding Machine Ppt Download